Some of our factories have achieved ISO9001:2015 certification and all factories follow ISO9001 quality management system. To guarantee the quality of our products, our Quality Department tests at least 4 times the whole process. The first time, the inspectors test the raw materials and take records when the raw materials arrive the plant. The second time, we carry out quality inspection during production. The third time, we carry out quality inspection before put it in storage. The fourth time, we spot check again before loading.

At the foot of Taihang Mountain, near the Hengshanlin Reservoir, we break down our raw ore by mechanical means after hole mining, then dry it with solar power in the air. The reserve of the raw minerals can last for decades.

There are two different manufacturing processes of mica powder-dry grinding without water and wet grinding with water. the manufacturing steps of dry ground mica powder are as following: mining--selection--crushing--refinement and winnowing--sieving--iron removal-packing.

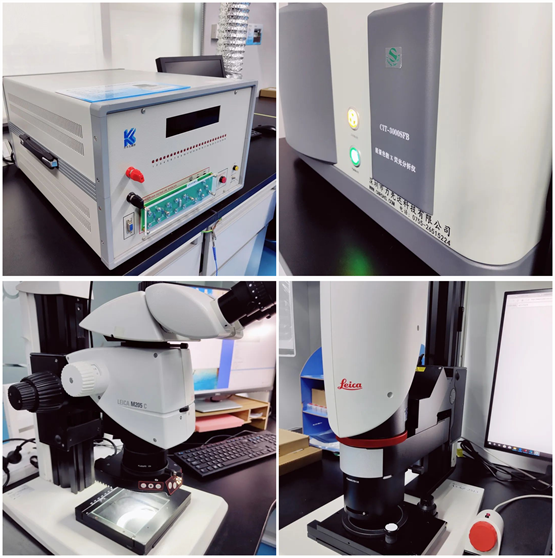

We have a mature management system which has been qualified by ISO 9001. Each process from ore mining to the final product package we all take records. Our own laboratory can do most of the quality tests and have the ability to customize product as required.

Color sand is made from marble or granite through selecting, crushing, grinding, grading, and packaging.We can produce about 50 different colors of sands.The plant capacity is 50 thousand tons one year.